We can transform your traditional company into a 5.0 company

How do we do it?

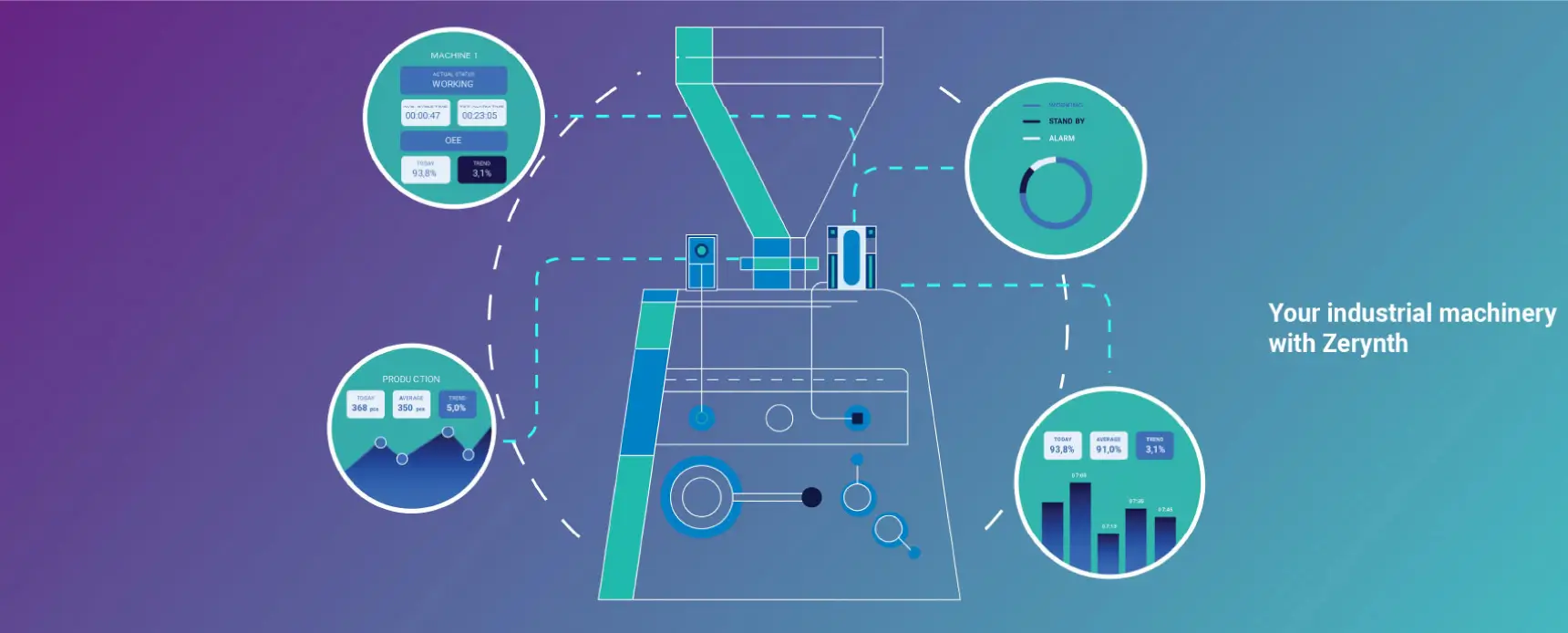

Get more from your machines

Produce more. Control more. Analyze more. Simply get more.

With Zerynth you squeeze the juice from your machinery to the last drop.

We can transform your traditional company into a 5.0 company

How do we do it?

Our IoT solutions guarantee the best user experience possible. You have our promise that everything will be fast, secure, and easy to implement.

What if you have problems?

Our experts are always at your service.

Get more from your machines

Produce more. Control more. Analyze more. Simply get more.

With Zerynth you squeeze the juice from your machinery to the last drop.

We can transform your traditional company into a 5.0 company

How do we do it?

Our IoT solutions guarantee the best user experience possible. You have our promise that everything will be fast, secure, and easy to implement.

What if you have problems?

Our experts are always at your service.

Industrial IoT & AI’s Zerynth solutions

Industrial IoT & AI’s Zerynth solutions

IoT for Machinery & Industrial Solutions Providers

Powering digital innovation in the industrial sector

IoT for Machinery & Industrial Solutions Providers

Powering digital innovation in the industrial sector

IoT for Machinery & Industrial Solutions Providers

Powering digital innovation in the industrial sector

Latest news

Latest news

Zerynth Customers

Zerynth helps customers to drive their industrial IoT transformation and deliver innovative products to the market.

Discover our partners

We continually foster relationships with industrial experts, technology leaders, and consultants to deliver results that exceed our clients’ expectations.

Get more value from your machines

Discover Zerynth Platform

Discover how to increase visibility on your production, streamline your processes, and enhance the value of your connected industrial products with the Zerynth IoT & AI Platform.

Latest news

Latest news

Zerynth Customers

Zerynth helps customers to drive their industrial IoT transformation and deliver innovative products to the market.

Discover our partners

We continually foster relationships with industrial experts, technology leaders, and consultants to deliver results that exceed our clients’ expectations.

Get more value from your machines

Discover Zerynth Platform

Discover how to increase visibility on your production, streamline your processes, and enhance the value of your connected industrial products with the Zerynth IoT & AI Platform.

Latest news

Latest news

About us

About us

Founded in 2015, Zerynth has grown steadily. Today it has 40+ team members with deep IoT expertise and industry knowledge with over 150 customers across many industries: from manufacturing to agriculture to energy to logistics.

Zerynth is based in Pisa, Italy, but also is active in international projects, and foresees an expansion both in EU and non-EU countries during the next three years.

About us

About us

Founded in 2015, Zerynth has grown steadily. Today it has 40+ team members with deep IoT expertise and industry knowledge with over 150 customers across many industries: from manufacturing to agriculture to energy to logistics.

Zerynth is based in Pisa, Italy, but also is active in international projects, and foresees an expansion both in EU and non-EU countries during the next three years.